Stainless steel mesh combines high light transmission with high EMI shielding. Lower mesh counts and thinner wire diameters allow for more light transmission. Higher mesh counts and thicker wire diameters give better EMI attenuation. Other advantages of stainless steel meshes are high resolution, very transparent, high tensile strength, extremely breathable,odorless, corrosion resistant, high temperature resistant, bendable, and very good uniformity.

stainless steel wire mesh materials

We maintains the largest selection of stainless steel grades to support customer’s needs,

304 stainless steel wire mesh

| C | Si | Mn | P | S | Ni | Cr |

| ≤0.07 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 8.00-11.00 | 17.00-19.00 |

304L stainless steel wire mesh

| C | Si | Mn | P | S | Ni | Cr |

| ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 8.00-12.00 | 18.00-20.00 |

316 stainless steel wire mesh

| C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 10.00-14.00 | 16.00-18.50 | 2.00-3.00 |

316L stainless steel wire mesh

| C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 12.00-15.00 | 16.00-18.00 | 2.00-3.00 |

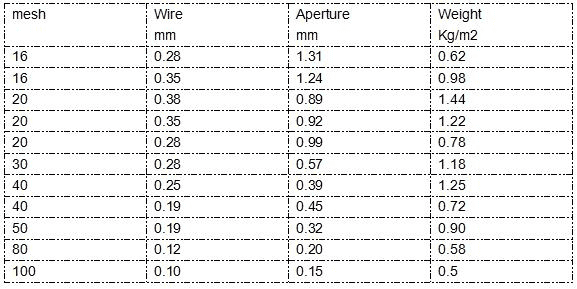

We offer and stock lots of standard mesh up to 1 meter wide and 30meters long , making it available when you need it.

Key benefits of using stainless steel wire mesh for RFI & EMI applications

Can be easily shaped to suit various application

Can assist avoiding the ‘Corona Effect’ (air around component becoming conductive)

Excellent fire and corrosion resistance

Available in stainless steel 304 304L 316 316L

Wide range of mesh sizes and open areas are possible.

stainless steel wire mesh for RFI & EMI applications

Leave a Reply