The manufacturing process of wedge wire screen in Web Wire Mesh involves several steps:

1. Manufacturing the V shaped wire

Wedge wire screen start with the utilization of high-quality raw wire. The primary raw material is the V-shaped profile wire, crafted through V-shaped rolling wire machines. Currently, our facility operates three sets of these machines to ensure efficient production. At Web Wire Mesh, we specialize in the professional fabrication of a diverse range of stainless steel wedge wire screens and alloy wedge wire screens, tailored to both standard and customized applications.

2. Manufacturing the cylinder or tubes:

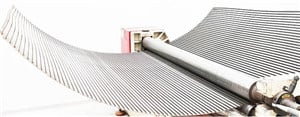

The wedge wire screen is manufactured by welding V-shaped profile wire around support rods in a cylindrical type, utilizing an automatic specialized wedge wire screen machine. Each profile wire and support rod undergoes resistance welding. The positioning of the support wire—whether internal or external—is determined by the flow direction. This welded construction results in wedge wire screens with exceptional strength and prolonged service life.

3. Wedge Wire Screen Deep Processing:

Our facility is equipped with cutting, welding, rolling, and forming machines to meet specific size and shape requirements as requested by customers. All wedge wire screens can undergo cutting, shaping, fabrication, and cleaning processes in our factory. Additionally, various edge types can be formed to create customized profiles tailored for specific applications.

Leave a Reply