The Common Wedge Wire Screen Terminologies please check the following

Open area rate–The percent open area of a Wedge Wire screen can be an important parameter when predicting flow capacity. Percent Open Area = ( Slot Opening / (Wire Width + Slot Opening)) x 100

FOTI —(filtration from outside to inside) Working surface outside: The triangular shaped slot performing profiles are welded with their wedge side to the inner crossbars. This is the most frequent design which makes the outside working surface smooth, thus allowing an easy cleaning from acumulated solids.

FITO–– (filtration from inside to outside) Working surface inside: The triangular shaped slot performing profiles are welded with their flat top side to the inner crossbars. In this design the flat working surface on the inside is interrupted by the position of the crossbars, thus making reverse flow the preferred cleaning method.

Non-Clogging—Wedge Wire Screens are fabricated by cylindrically wrapping a continuous V-shaped wire around axial support rods. The uninterrupted slot formed allows for only two points of contact with particles on the screen surface to minimize clogging. This means that the maximum effective flow area and operating efficiency are maintained.

Profile Wire –Profile wire is rolled from a round wire through a series of rolling and annealing operations. Larger cross sections may be die drawn to size.With the use of high-quality materials, profile wires meet the highest requirements. The range of products includes all common profile wires –from the standard profile wire to our low-wear PW profiles.Other profile variants can be supplied upon request.

Profile Wire also known as wedge wire, V-wire, Tri-wire or surface profiles, it allows a high level of precision and efficiency in screening applications. The wedge shape of Profile Wires provides a large opening (conical slots in case of V-shaped profile wires) for material to flow between the wires.Profile wires increase screening efficiency by substantially reducing blinding and pegging.

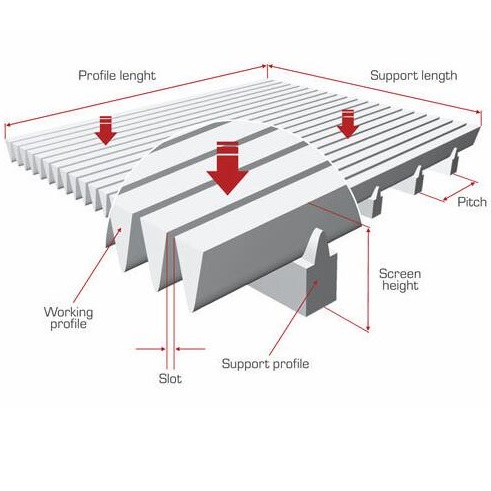

Slot Size–It means the clear distance between any two adjacent profile wires. Slot size is controlled very accurately as it forms the slot through which the filtrate flows.

Support Rod–Support wire is rolled from a round wire through a series of rolling and annealing operations. Larger cross sections may be die drawn to size.It is also known as support profiles, onto which surface profiles are resistance welded. Support rod includes triangle wire, round bar, flat bar and wedge wire.

Depending on the application, requirement and the profile wire chosen, there are a multitude of support wires available. Web is ready with advice in the selection of the optimal support wire variant / profile wire combination so as to achieve process reliability and the maximum service life.

Support Rod Distance–It means the clear distance between any two adjacent support rods.

Diameter–-the diameter of the wedge wire screen tube

Length–the length of the wedge wire screen tube or panel

Width–the width of the wedge wire screen panel

Diagonal line–It is the straight line that connects the opposite corners of a square or rectangle wedge wire screen panel through its vertices.

Leave a Reply